Understanding SEW Brake Function

Introduction to SEW Brake Function

SEW brakes help machines stop safely and work well. Whether you’re working with industrial equipment or DIY projects, understanding SEW brake function is essential. These brakes control the movement of machines, letting them stop and hold their position when needed. This is especially important in applications where precise movement is required, like in robotics or manufacturing.

But why is it so crucial to have a deeper understanding of SEW brake function? Simply put, knowing how these brakes operate helps you troubleshoot problems, maintain your equipment, and ensure everything runs smoothly. When a machine doesn’t stop correctly, it can lead to accidents or damage, costing time and money. By learning about SEW brakes, you can prevent these issues and keep your projects on track.

This section sets the stage for the rest of the article by introducing you to what SEW brakes are and where they’re commonly used. How this brake actually functions will be covered in more detail in the following sections. It’s not just about knowing the parts—it’s about knowing how those parts work together to keep your machinery safe and efficient. So, let’s dive in and explore why gaining this knowledge is vital for anyone working with machines.

How SEW Brakes Actually Function

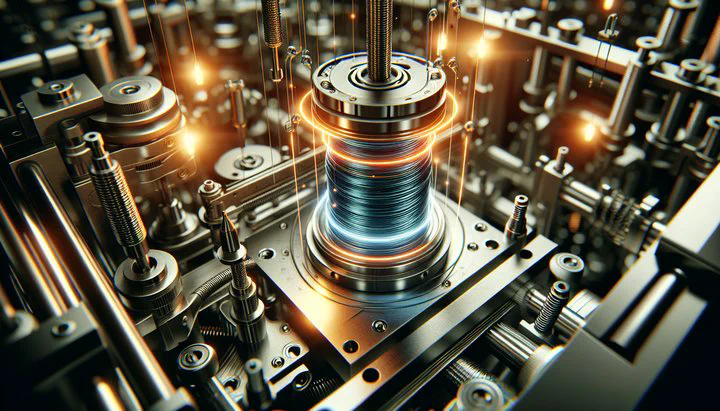

To truly grasp the understanding of SEW brake function, you need to know how these brakes operate within a system. SEW brakes have key components that work together to control machinery. At the heart of an SEW brake is the electromagnetic coil. When the coil is energized, it creates a magnetic field that pulls the brake armature away from the friction disc, allowing the machine to move freely. When the coil is de-energized, the armature presses against the friction disc, stopping the machine.

Let’s break down the mechanics of how this brake actually functions. The coil, armature, and friction disc are the main players. When power is applied to the coil, it creates a magnetic force. This force moves the armature away from the friction disc, releasing the brake and enabling the machinery to operate. When the power is cut off, the magnetic force disappears, and a spring pushes the armature back against the friction disc, bringing the machinery to a halt. This simple yet effective mechanism ensures precise stopping and holding capabilities.

An important aspect of SEW brakes is their ability to provide a reliable and consistent braking force. This ensures machinery can stop quickly and safely, which is vital in preventing accidents and maintaining efficiency. Understanding the role of each component in the brake system helps you see why it’s essential to make use of the full coil. Using just a part of the coil can lead to reduced braking power and increased wear on the components.

In summary, the function of SEW brakes relies on the harmonious operation of the coil, armature, and friction disc. By creating and releasing magnetic forces, these brakes manage the movement of machinery with precision. As you continue to explore SEW brakes, keep in mind the importance of the full coil in ensuring optimal performance and longevity. This knowledge will help you maintain your equipment and troubleshoot any issues that may arise.

The Importance of Using the Full Coil

When it comes to SEW brakes, using the full coil is crucial for optimal performance and long life. The coil is designed to generate a magnetic field strong enough to control the brake armature effectively. By making use of the full coil, you ensure that the brake operates at its full potential, providing the necessary force to stop and hold machinery safely.

You might wonder why using the complete coil is so important. The design of the SEW brake depends on the magnetic field created by the coil to function correctly. If you use just a part of the coil, the magnetic force is weaker, making it harder for the brake to engage properly. This can lead to slower stopping times and increased wear on the brake components, resulting in more frequent maintenance and repairs.

Moreover, using the full coil helps distribute the electrical load evenly across the entire coil, preventing hotspots and overheating. Over time, partial use of the coil can lead to uneven wear and potential coil failure. By ensuring you use the entire coil, you help maintain the brake’s efficiency and reliability, reducing the risk of unexpected breakdowns.

In essence, the full coil is designed to provide the consistent and robust magnetic force needed for safe and effective braking. Ignoring this design can compromise the brake’s function, leading to performance issues and increased maintenance costs. So, remember, using the entire coil is not just a recommendation—it’s a necessity for keeping your machinery running smoothly and safely. This understanding will empower you to maintain your equipment better and prolong the life of your SEW brakes.

Implications of Using Only Part of the Coil

Using only part of the coil in SEW brakes can lead to several significant issues that affect both performance and safety. When you rely on just a portion of the coil, you might not get the full magnetic force needed to operate the brake effectively. This means that the brake may not engage as quickly or as forcefully as it should, which can be dangerous in situations where precise stopping is crucial.

One major drawback is the increased mechanical stress on the brake components. The armature, for instance, may not be pulled away from the friction disc efficiently, causing it to drag or wear unevenly. This can lead to faster wear and tear, resulting in more frequent maintenance and possible unexpected failures.

Using only part of the coil can make the brake work less well. With less magnetic force, the brake’s ability to stop and hold machinery diminishes, leading to longer stopping distances and less reliable operation. In industrial settings, where safety and precision are paramount, these performance issues can cause significant disruptions and even pose risks to operators.

Moreover, partial use of the coil can cause electrical imbalances within the brake system. This can result in overheating and potential damage to the coil itself, leading to costly repairs or replacements. By understanding the importance of using the full coil, you can avoid these pitfalls and ensure your SEW brakes function as intended.

In summary, using only part of the coil compromises the effectiveness and safety of SEW brakes. It can lead to increased wear, performance issues, and potential mechanical failures. To keep your machinery running smoothly and safely, it’s essential to use the entire coil as designed. This deeper understanding of SEW brake function will help you maintain your equipment better and avoid unnecessary problems down the line.

Conclusion and Practical Tips

In wrapping up our exploration of SEW brakes, it’s clear that having a deeper understanding of SEW brake function is essential for anyone working with these critical components. By understanding how this brake actually functions, you can ensure that your machinery operates safely and efficiently. It’s not just about knowing the parts—it’s about knowing how they work together to stop and hold machines precisely when needed.

One of the most important takeaways is the necessity to make use of the full coil. As we’ve discussed, using the entire coil ensures the brake generates the full magnetic force required for optimal performance. Ignoring this can lead to reduced braking efficiency, increased wear, and even potential failures. By using the full coil, you help maintain the brake’s reliability and prolong its lifespan.

Now, let’s focus on some practical tips to keep your SEW brakes in top shape. First, regularly inspect your brakes for signs of wear or damage. Look for uneven wear on the friction disc or any signs of overheating on the coil. Routine checks can help you catch issues early and prevent costly repairs down the line.

Second, ensure that your electrical connections are secure and that the coil receives a consistent power supply. Fluctuations in power can affect the brake’s performance, so maintaining stable electrical input is crucial.

Finally, join the discussion on MakerTechGuides to share your tips and learn from others. Engaging with the community can provide valuable insights and help you tackle any challenges you might face with SEW brakes. By being part of a community, you can stay updated on best practices and new techniques.

In conclusion, understanding SEW brakes and making proper use of their components, especially the full coil, is key to maintaining safe and efficient machinery. Armed with this knowledge and these practical tips, you’re well-equipped to handle any issues that arise and keep your projects running smoothly.

Related

- Effectively Managing TIA Software Changes with VM Snapshots

- Mastering Auto-Complete with Shared VarSets in FreeCAD

- Troubleshooting Flashforge Adventurer 4 Printing Issues

- Troubleshooting Issues When Moving ViewME Project Folder to OneDrive

- Mastering Macros in FreeCAD for Object Copying with Internal Names