Solving Bumpy Top Surfaces in 3D Printing

Solving Bumpy Top Surfaces in 3D Printing

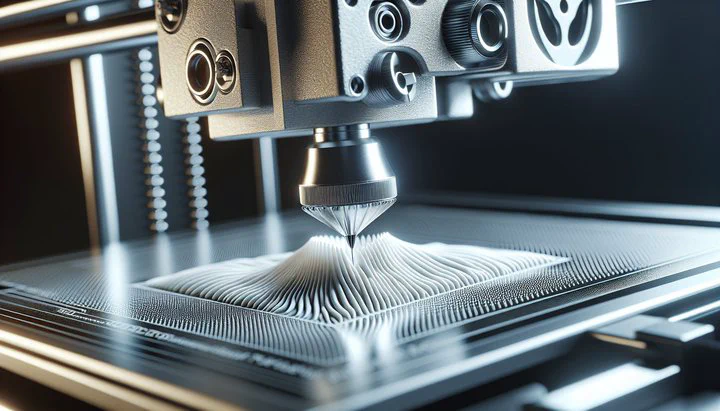

Have you ever finished a 3D print only to find the top surface looking less than perfect? Like a series of tiny steps instead of a smooth finish? You’re not alone! This is a common issue many 3D printing enthusiasts face. The top surface might not come out as smooth as you expected, and instead, you see tiny little gaps that can be frustrating. Understanding why this happens is the first step to solving the bumpy top surface in 3D printing.

When the top of your 3D print doesn’t look right, it often involves terms like top layer stepping or random gaps on the top surface. These issues mean that the layers aren’t perfectly aligned, causing the surface to appear uneven. Sometimes, you might see spaces between the lines of filament, which can create those pesky bumps and gaps.

To help you picture this, imagine building a staircase. If each step isn’t placed perfectly on top of the previous one, the staircase will look uneven. That’s similar to what’s happening with your 3D print. When layers don’t sit just right, you end up with a top surface that looks like a series of small steps or gaps.

Visual examples can be really helpful here. Imagine holding a printed object and seeing small ridges or lines where the top layer didn’t fill in smoothly. This is often due to not having enough top layers or the layers being too thin. These symptoms are signs that adjustments are needed to achieve a smooth finish.

In the next sections, we’ll dive deeper into what causes these bumpy top surfaces and how you can fix them. Remember, every problem has a solution, and soon you’ll be on your way to printing flawless, smooth top surfaces!

Identify and Address Common Causes of Bumpy Top Surfaces

Now that you know what bumpy top surfaces look like, let’s talk about why they happen. Understanding these causes will help you in solving bumpy top surface issues in 3D printing.

One of the most common reasons for a bumpy surface is incorrect layer height. If your printer’s layer height settings are not just right, the layers won’t stack properly. This can cause the top of your print to appear uneven, similar to how a staircase looks if the steps are uneven. When the layer height is too high or too low, it can lead to issues like top layer stepping, where each layer doesn’t align perfectly, creating those unwanted steps and gaps.

Another culprit could be insufficient top layers. If you don’t have enough layers on the top of your print, the surface might not fill in completely, leading to random gaps on the top surface. Imagine trying to cover a table with a thin cloth. If the cloth isn’t thick enough, you can see the table underneath. Similarly, if there aren’t enough top layers, the infill pattern might show through, causing a bumpy appearance.

Filament quality also plays a big role. If you’re using filament that’s old, moist, or just low quality, it might not extrude properly. This can result in tiny little gaps on the top surface of your print. Always ensure your filament is dry and of good quality to avoid these problems. Poor filament can cause inconsistent extrusion, leading to surfaces that are less than perfect.

Lastly, consider your printer settings and environment. Sometimes, the issue could be due to temperature fluctuations or improper bed leveling. If the print bed isn’t level, it can affect how each layer is laid down, leading to an uneven surface. Similarly, if the temperature settings aren’t right, it can affect how the filament flows, contributing to bumpy surfaces.

By identifying these common causes, you’re one step closer to solving the bumpy top surface issues in your 3D prints. In the following sections, we’ll guide you on how to fix these problems and achieve smoother top surfaces.

Step-by-Step Guide to Fix Bumpy Top Surfaces

Ready to make your 3D prints look amazing? Let’s dive into solving bumpy top surface issues in 3D printing with some easy-to-follow steps. By adjusting a few settings and making small changes, you can achieve those smooth top surfaces you’ve been aiming for.

-

Adjust Your Layer Height: Start by checking your printer’s layer height settings. If the layers are too thick or too thin, they won’t line up right, causing top layer stepping. Try setting your layer height to about 20% of your nozzle diameter. For example, if you have a 0.4mm nozzle, a layer height of 0.08mm to 0.12mm usually works well.

-

Increase the Number of Top Layers: One simple fix for those tiny little gaps on the top surface is to add more top layers. If you can see infill patterns through the top, it means you need more layers to cover them up. A good rule of thumb is to have at least six top layers. This will give the top surface enough material to fill in smoothly.

-

Optimize Your Print Speed: Sometimes, going too fast can cause problems, like random gaps on the top surface. Slow down your print speed, especially for the top layers. Try reducing it to about 50% of your normal print speed to allow the layers to set properly.

-

Enhance Filament Quality: Make sure your filament is in top condition. Poor quality filament can lead to inconsistent extrusion and bumpy surfaces. Keep your filament dry by storing it in a sealed container with desiccant. If you notice quality issues, try using a better filament brand.

-

Level Your Bed: An uneven print bed can cause layers to not adhere properly, leading to a bumpy like a set of stairs effect. Make sure your bed is perfectly level before each print. Use a piece of paper to check the gap between the nozzle and bed, adjusting until you feel slight resistance as the paper slides through.

-

Fine-Tune Temperature Settings: If the filament isn’t melting and sticking properly, it might be due to incorrect temperature settings. Increase the nozzle temperature by 5-10 degrees Celsius to see if it improves the top surface finish. Make sure the temperature is appropriate for your specific filament type.

Give these steps a try, and you’ll be amazed at the difference they make! Remember, a bit of patience and small adjustments can make a big difference. Next up, we’ll explore more advanced techniques for those persistent issues that just won’t go away. Keep experimenting and happy printing!

Advanced Troubleshooting Techniques

If you’ve tried the basics and still face challenges with bumpy top surfaces, don’t worry. Sometimes, getting that perfect finish requires a bit more finesse. Let’s explore some advanced techniques to help you solve those stubborn issues in 3D printing.

-

Fine-Tuning Temperature Settings: Temperature plays a critical role in how your layers bond. If you notice your top layer isn’t smoothing out, try adjusting the nozzle temperature. Increasing by just a few degrees might help the filament flow better, reducing tiny little gaps on the top surface. However, be cautious not to overheat, as this can cause other issues like stringing or blobs.

-

Use Specialized Slicer Settings: Your slicer software has powerful tools to help improve print quality. Look into settings like “top solid infill” or “ironing” if your slicer supports them. These options can help smooth out the top layers by ensuring even deposition of filament, reducing the appearance of a surface that’s bumpy like a set of stairs.

-

Experiment with Different Materials: Sometimes, the filament you’re using might not be the best fit for your specific print. Try experimenting with different types or brands. Some filaments are specifically designed for smoother finishes and might help eliminate those random gaps on the top surface. Consider testing with a high-quality PLA or a filament known for its consistent extrusion.

-

Optimize Cooling Settings: Proper cooling can influence how well the filament sets. If the top layers of your print aren’t bonding well, try adjusting the fan speed. Too much cooling can cause poor adhesion, leading to gaps. Conversely, inadequate cooling might not allow the filament to set properly, causing surface imperfections.

-

Check for Mechanical Issues: Sometimes, persistent problems can be due to mechanical issues with your printer. Check for loose belts, misaligned axes, or worn-out parts that could affect print quality. Ensuring your printer is in top shape can prevent issues like top layer stepping and improve overall performance.

If you’ve tried all these advanced techniques and still face problems, it might be helpful to reach out to the community. Online forums and subreddits like “3Dprintmything” or “3DPrinting” can offer valuable advice and support from fellow enthusiasts. Sharing your experiences and learning from others can lead to new solutions you might not have considered.

Remember, the key to solving bumpy top surfaces in 3D printing is patience and persistence. Keep fine-tuning your approach, and soon you’ll achieve the smooth, flawless prints you’re aiming for. In the next section, we’ll discuss how to prevent these issues from occurring in future projects. Keep experimenting, and happy printing!

Preventing Bumpy Top Surfaces in Future Prints

You’ve tackled the challenge of solving bumpy top surfaces in 3D printing, but how do you ensure these problems don’t come back? Prevention is key to maintaining smooth, professional-looking prints. Here are some strategies to help you keep those pesky bumps at bay in future projects.

-

Regular Printer Maintenance: Keeping your printer in top shape is crucial. Make it a habit to regularly check for loose screws, worn-out parts, and misaligned components. A well-maintained printer is less likely to produce prints with issues like top layer stepping or random gaps on the top surface. Clean your printer’s nozzle and bed to ensure smooth operation.

-

Use High-Quality Filaments: Filament quality can make a big difference in print results. Invest in good-quality filament to minimize the risk of tiny little gaps on the top surface. Store your filaments in a dry, cool place, using airtight containers with desiccant to prevent moisture absorption, which can lead to poor print quality.

-

Perform Test Prints: Before starting a big project, run a few test prints. This allows you to adjust settings and catch potential problems early. Use small models to test for any bumpy like a set of stairs effects and tweak your printer settings as needed. This proactive approach can save time and materials in the long run.

-

Document Your Settings: Keep a detailed log of your printer settings for different materials and projects. This record helps you replicate successful prints and troubleshoot future issues more effectively. Note down the layer height, temperature settings, print speed, and any other relevant parameters for each print.

-

Stay Informed and Connected: The world of 3D printing is constantly evolving. Stay updated with the latest tips and techniques by joining online communities and forums. Engaging with groups like “3DPrinting” on Reddit can provide insights and help you learn from others’ experiences. Sharing your own successes and challenges can also contribute to the community’s knowledge.

By following these preventive measures, you’ll be well-equipped to avoid the frustrations of bumpy top surfaces in your future 3D printing endeavors. With the right preparation and consistent care, your prints will come out smooth and impressive every time. Keep experimenting, and happy printing!

Share your own tips or ask questions in the comments below! We’d love to hear how these solutions worked for you.