Effective Solutions for Data Collection on Old Machinery

Smart Solutions to Collect Data from Old Machinery

Ever wondered how to make your old machines smarter? If you’re trying to find a solution to collect data on old machinery, you’re not alone. Many industries still rely on older equipment that lacks modern connectivity. This makes it tough to gather useful data. These machines were built before sensors and internet connections became standard. Without these features, it’s hard to track how well the machinery is working or when it might need maintenance.

Data collection from old machinery is important because it helps optimize operations. By understanding how machines perform over time, you can prevent breakdowns, improve efficiency, and save money on repairs. But without built-in sensors and connectivity, collecting this data is a real challenge. You need to find modern solutions to gather the information you need.

One of the biggest hurdles is the absence of built-in sensors. Older machines weren’t designed to send out data about their performance. This means you need to find ways to add sensors or other devices to collect this information. Another issue is the lack of connectivity. Without the ability to connect to a network, these machines can’t send their data to a central system for analysis.

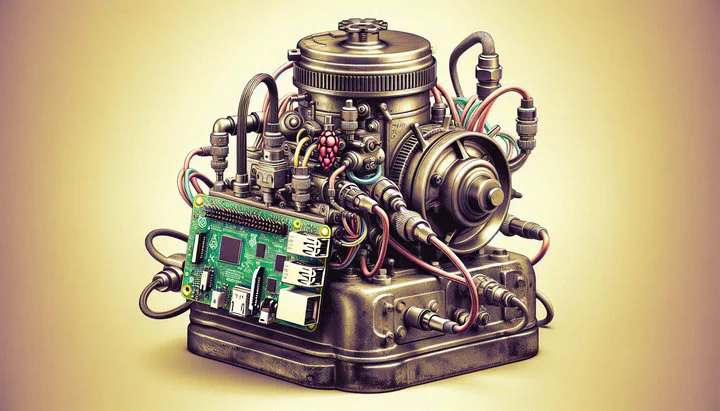

To overcome these challenges, you’ll need to explore technology solutions that can bridge the gap between old and new. This includes using devices like IoT-Couplers and Raspberry Pis to enable data acquisition. These modern tools can help you gather the operational data you need, even from old machinery that wasn’t designed with data collection in mind. By finding the right approach to data acquisition, you can unlock valuable insights and improve your operations.

Leveraging IoT-Couplers for Data Acquisition

To solve the problem of collecting data from old machinery, you can use IoT-Couplers to collect operational data. IoT-Couplers are small devices that connect to your old machines, allowing them to communicate with modern data systems. They act like a bridge, connecting the past with the present by enabling real-time data monitoring.

So, how do IoT-Couplers work? These devices attach to different parts of your machinery, such as motors or temperature gauges, to pick up signals. Once connected, they send this information over the internet to a place where it can be analyzed. This is a big advantage because it means you can watch your machine’s data as it happens, catching problems early and optimizing performance.

Using IoT-Couplers can transform your old machinery into smart equipment. This transformation is crucial because it allows you to gather data without making big changes to your existing setup. The approach to collecting data using IoT technology is efficient and cost-effective. You won’t need to replace your entire fleet of machines; instead, you can enhance them with these handy devices.

Another benefit of using IoT-Couplers is the real-time data acquisition and monitoring they offer. You can keep an eye on how your machines are doing at any moment, from anywhere. This helps in making quick decisions, improving productivity, and reducing downtime. Overall, IoT-Couplers provide a powerful solution to collect data on old machinery, making your operations smoother and more efficient.

Implementing Raspberry Pis with Locked Memory Cards

Using Raspberry Pis with locked memory cards is a smart way to enhance data collection from old machinery. Raspberry Pis are small, affordable computers that can be used to gather and process data from your equipment. By connecting them to IoT-Couplers, you can create a powerful system for data collection.

To set up a Raspberry Pi for this purpose, you need to connect it to your IoT-Couplers. The Raspberry Pi acts as a hub, receiving the data collected by the IoT-Couplers. It processes this information and stores it securely on its memory card. Using locked memory cards is important because it prevents accidental data loss or tampering, ensuring your data remains safe and reliable.

Here’s a simple guide to setting up your Raspberry Pi system. First, install the necessary software on your Raspberry Pi to allow it to communicate with the IoT-Couplers. Next, connect the Raspberry Pi to your old machinery through the IoT-Couplers. Finally, insert a locked memory card into the Raspberry Pi to securely store the data. This setup is not only efficient but also provides peace of mind knowing your data is protected.

The advantage of using Raspberry Pis is their flexibility and affordability. They can be easily programmed to meet your specific data collection needs. By using this approach, you can tailor your data collection system to fit the unique requirements of your machinery, without breaking the bank.

Incorporating Raspberry Pis with locked memory cards into your data collection strategy offers secure and efficient data storage. This solution makes it possible to gather valuable insights from your old machinery, helping you optimize operations and make informed decisions. With this setup, you can ensure that your data collection process is both reliable and robust, paving the way for improved performance and productivity.

Making Signals Available with IoT Couplers

By using IoT Couplers, you can effectively use IoT couplers to make signals available from your old machinery. This step is crucial for transforming raw signals into usable data that can be analyzed to improve your operations. IoT Couplers work by connecting to various parts of your machinery and capturing signals that can then be sent to your data system.

When you attach IoT Couplers to your machinery, they pick up signals from different components like motors or sensors. These signals are often raw and not immediately useful. The IoT Couplers convert these raw signals into a format that can be easily understood and analyzed by your data systems. This transformation is what makes the data accessible and useful for decision-making.

The process of making signals available involves a few technical steps, but it’s manageable with the right guidance. First, you need to identify the key points on your machinery where data can be collected. Next, attach the IoT Couplers to these points to start capturing signals. Finally, ensure the IoT Couplers are connected to a network so the signals can be transmitted for analysis.

Making signals available with IoT Couplers greatly enhances data accessibility and usability. This means you can gain insights into how your machinery is performing, spot potential issues early, and make informed decisions to optimize your operations. With IoT Couplers, your old equipment can become a source of valuable data, helping you stay competitive and efficient.

An example of this in action is a small factory that used IoT Couplers to monitor the performance of its aging assembly line. By collecting data from their machines, they were able to predict maintenance needs and reduce unexpected downtime, leading to smoother operations and increased productivity.

Overall, using IoT Couplers provides an effective solution to collect data on old machinery by making signals available for analysis. This approach to data acquisition bridges the gap between outdated equipment and modern technology, unlocking new possibilities for operational improvement and innovation.

Conclusion and Future Prospects

In this article, we’ve explored smart solutions for collecting data from old machinery. By using IoT-Couplers to collect operational data and integrating Raspberry Pis with locked memory cards, you can transform your outdated equipment into smart machines. These tools help you gather real-time data and make informed decisions, improving efficiency and reducing downtime. This approach to collecting data not only enhances your current operations but also prepares you for future advancements.

The integration of IoT technology with legacy machinery opens up exciting possibilities for industrial optimization. As technology continues to evolve, these solutions will become even more powerful and accessible. The ability to use IoT couplers to make signals available ensures that even the oldest machines can contribute valuable insights, driving innovation and competitiveness in your operations.

Looking ahead, the future of data collection in industrial settings is bright. As IoT technology and data acquisition methods advance, you’ll have even more options to enhance your machinery and processes. Imagine a world where all your equipment communicates seamlessly, predicting maintenance needs and optimizing performance without human intervention. By embracing these technologies today, you’re paving the way for a smarter, more efficient future.

We encourage you to start small by trying out one of the solutions discussed. Implementing these technologies might seem challenging at first, but the rewards are worth it. With the right tools and guidance, you can unlock the full potential of your old machinery, ensuring your business stays ahead in a rapidly changing world.

Related

- How to Bind Fabric Pieces Together- A Comprehensive Guide

- Utilizing a 1 Ohm Resistor with Festo Multi-Pin Plugs for Enhanced Circuit Performance

- Effective Techniques to Maintain the Shape of Breast Cups

- Exploring Flexible Materials for Wing Props

- How to Find and Replace the Eccentric Bushing in a DJ-15 Delta Jointer