Pros and Cons of Benchtop Mills Under 900 lbs

Introduction to Benchtop Mills Under 900 lbs

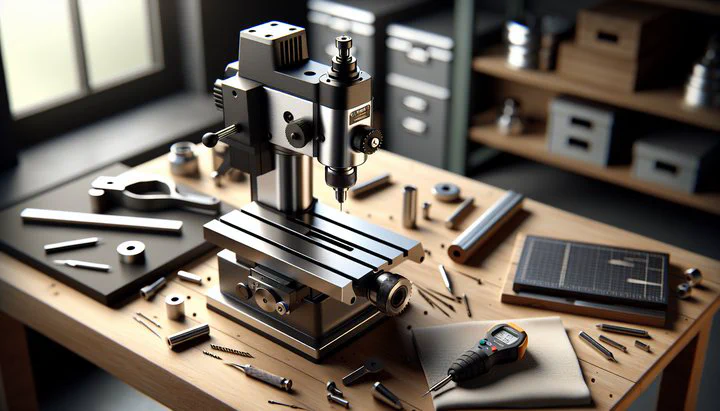

If you’re a maker or an engineer, you might have heard about benchtop mills. These machines are a fantastic choice for small workshops because they are compact and versatile. A benchtop mill is a type of milling machine that is small enough to fit on a workbench. They are perfect for tasks like shaping metal or wood, drilling holes, and making precise cuts. But what makes benchtop mills that weigh under 900 lbs so popular?

Benchtop mills under 900 lbs are especially favored because they strike a sweet balance between size and power. They are light enough to move around if needed, yet sturdy enough to handle a variety of tasks. These mills can be essential for hobbyists and professionals who need precision but don’t have space for a large, heavy machine. Their compact size means they can fit into tight spaces, making them ideal for home workshops or garages where space is often limited.

One of the biggest advantages of these mills is their ability to handle many different projects. You can use them for crafting custom parts or repairing machinery. Because of their manageable size and weight, they’re easier to set up and operate. Plus, they tend to be less expensive than larger, industrial mills, so they’re a great option if price is a concern.

In summary, benchtop mills under 900 lbs offer a great combination of size, power, and affordability, making them a popular choice among makers and engineers. Whether you’re just starting out or you’re an experienced machinist, these mills can help you with a wide range of projects. As you explore the options available, keep in mind the pros and cons of benchtop mills under 900 lbs to ensure you find the perfect fit for your needs.

Biggest Possible ‘Benchtop’ Mill Under 900 lbs

If you’re shopping for the biggest possible ‘benchtop’ mill under 900 lbs, here’s what you need to know. You’re looking for a machine that offers the most space and power while still being compact. These larger benchtop mills are great because they give you more room to work with bigger pieces without taking up too much space in your workshop.

Some of the largest benchtop mills that fall under the 900 lbs weight limit include models like the Grizzly G0704 and the Precision Matthews PM-25MV. These mills come with features like strong motors and sizable worktables, allowing you to handle more extensive projects. The Grizzly G0704, for instance, has a powerful motor and a large table, which makes it perfect for more demanding tasks. Similarly, the Precision Matthews PM-25MV offers a great mix of size and power, making it a favorite among many hobbyists.

However, it’s important to remember that as you increase the size of the mill, you might also need to think about how it fits in your workspace. While larger benchtop mills provide more capability, they can also take up more room, which may not be ideal if you’re working in a tight space. Balancing size with your workspace is crucial to ensure you have enough room to work comfortably without feeling cramped.

In addition to considering the size, you should also look at the mill’s features and how they impact performance. Bigger benchtop mills typically have more stable and sturdy frames, which can improve precision and reduce vibrations. This means your projects can be more accurate and professional-looking. Always weigh these benefits against the available space in your workshop to make the best decision.

In conclusion, when searching for the biggest possible ‘benchtop’ mill under 900 lbs, focus on finding a machine that offers the best balance between size, power, and workspace efficiency. These mills can greatly enhance your ability to complete various projects while still fitting within your space and budget constraints.

The Importance of an R8 Spindle

When you’re considering a benchtop mill, you’ll often hear that an R8 spindle is a must. But what exactly does this mean, and why is it so important? The spindle is the part of the mill that holds the cutting tool, and the R8 spindle is a specific type that is widely used and appreciated for its versatility and ease of use.

The R8 spindle is popular because it makes changing tools quick and easy. This is especially helpful if you’re working on a project that requires different tools for various cuts. Instead of spending a lot of time swapping tools, the R8 spindle allows you to change them efficiently, keeping your workflow smooth and uninterrupted. This feature can save you both time and frustration, making your milling tasks more enjoyable.

Another reason why an R8 spindle is favored is its compatibility. Many milling machines and tools are designed to work with the R8 spindle, which means you have a wide range of tools to choose from. Whether you need a specific drill bit or a cutting tool, there’s a good chance it’s available in an R8-compatible version. This flexibility is invaluable for both beginners and experienced machinists, as it lets you tackle a variety of projects without being limited by your equipment.

Additionally, using an R8 spindle can improve the performance and precision of your benchtop mill. The design of the R8 allows for a secure fit, which reduces vibrations during operation. Less vibration means your cuts are smoother and more accurate, resulting in professional-looking projects. For makers and engineers who value precision, this is a significant advantage.

In summary, the R8 spindle is a must for many users because it offers ease of tool changes, wide compatibility, and enhanced performance. When selecting a benchtop mill, considering the type of spindle is crucial. An R8 spindle can greatly expand your capabilities and improve the quality of your work, making it a worthy investment for any serious maker or engineer.

Balancing Quality and Price

If you’re shopping for a benchtop mill under 900 lbs, you’ll quickly notice that quality is important, but so is finding a mill that fits your budget. Balancing these two factors can be tricky, but with a few tips, you can make a smart choice that won’t break the bank.

First and foremost, look at the build quality of the mill. A well-made machine should have a sturdy, durable frame and precise moving parts. This ensures that the mill will last a long time and perform accurately. Check for materials like cast iron, which is known for its strength and stability. A solid build not only extends the life of the mill but also improves performance, giving you better results on your projects.

Next, consider the features that are most important to you and how they impact the price. Some mills come with advanced features like digital readouts or variable speed controls, which can make your work easier and more precise. However, these features might also increase the cost. Decide which features are must-haves and which ones you can do without. This helps you focus on getting the best quality within your budget, ensuring price is a concern that’s well-addressed.

It’s also helpful to compare different models and brands. Some companies offer high-quality mills at competitive prices, providing great value for money. For instance, brands like Grizzly or Precision Matthews are known for producing reliable benchtop mills that balance quality and affordability. Reading reviews and getting recommendations from other makers can guide you to the best options available.

Finally, think about long-term costs. A cheaper mill might save you money upfront, but if it requires frequent repairs or replacements, it could end up costing you more in the long run. Investing in a quality mill initially can save you both time and money over the years. Look for models that come with good warranties, as they often indicate a manufacturer’s confidence in their product’s durability.

In conclusion, while quality is important when selecting a benchtop mill, keeping an eye on price is a concern that shouldn’t be overlooked. By evaluating the build quality, essential features, and long-term value, you can find a mill that meets your needs without stretching your budget too thin. This careful consideration ensures that your investment in a benchtop mill is both wise and rewarding.

Conclusion and Buying Tips

As we’ve explored throughout this article, there are many pros and cons of benchtop mills under 900 lbs. These compact machines offer a great blend of size, power, and affordability, making them a popular choice for makers and engineers. Whether you’re looking for the biggest possible ‘benchtop’ mill under 900 lbs or one with an R8 spindle is a must, there are several factors to consider when making your decision.

First, always think about the space you have available. Make sure the mill you choose fits comfortably in your workshop without cramping your work area. Also, consider the types of projects you plan to undertake. If you need more versatility, look for a mill with features like an R8 spindle, which allows for quick and easy tool changes.

Next, balance quality with price. Remember, quality is important for long-lasting performance and precision, but price is a concern that must align with your budget. Look for mills with a sturdy build and the features you need, without overspending on extras that may not be necessary for your work.

Here are a few practical buying tips:

-

Make a Checklist: List out the features you need most, such as spindle type, table size, and speed options. This can help you stay focused and avoid getting distracted by unnecessary features.

-

Read Reviews: Check online reviews and ask for recommendations from other makers or engineers. This can provide valuable insights into the performance and reliability of different models.

-

Consider Long-term Costs: Think about maintenance, repair costs, and potential upgrades when evaluating the overall price of a mill. Sometimes spending a bit more upfront can save money down the line.

-

Check Warranties and Support: Opt for a mill that comes with a good warranty and reliable customer support. This can be a lifesaver if you encounter any issues with your machine.

In summary, choosing the right benchtop mill under 900 lbs involves weighing the pros and cons carefully. By considering your space, project needs, quality, and budget, you can find a mill that suits your specific requirements. This thoughtful approach ensures that your investment will be both practical and satisfying, empowering you to tackle your projects with confidence.

Explore more articles on MakerTechGuides, join community discussions, or try a specific project using a benchtop mill. Happy milling!