PLC I/O Buffering Best Practices

Introduction to PLC I/O Buffering

Welcome to the world of PLC I/O buffering! If you’re diving into PLC systems, you’ve come to the right place. Let’s start by breaking down what I/O buffering is and why it’s so important.

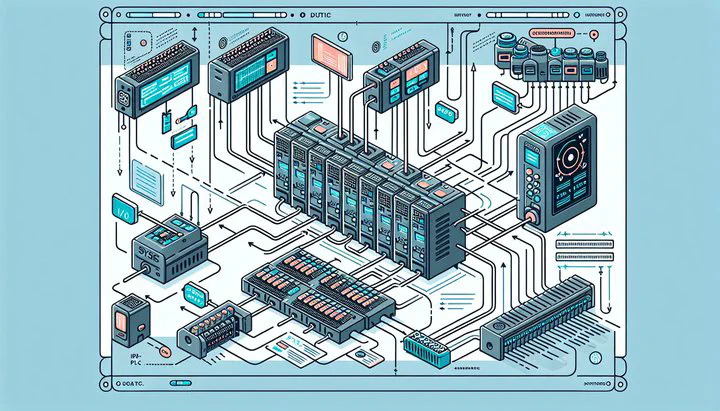

In a PLC system, I/O stands for Input/Output. These are the signals that come into the system from sensors or other devices and go out to control things like motors or lights. Now, imagine if all these signals tried to rush in and out at once. It could get pretty chaotic, right? That’s where I/O buffering comes in. It’s like a traffic controller that manages the flow of signals, ensuring everything runs smoothly. This management is crucial because it helps your system perform better and keeps it from getting overwhelmed.

So, why should you care about buffering in PLC systems? Well, proper buffering can make your PLC system faster and more reliable. It helps your system respond quickly to changes and keeps everything running efficiently. When you organize and map out your I/O effectively, you improve not just the performance but also the maintainability of your system. It’s like having a neat and tidy workspace — everything is easier to find and use!

By understanding PLC I/O buffering best practices, you’re setting yourself up for success. Whether you’re a hobbyist tinkering in your garage or an engineer working on complex systems, knowing how to handle I/O buffering will make your projects run smoother. So, stick around, and we’ll explore more about how you can implement these practices using tools like Studio 5000.

Best Practices for Mapping and Buffering I/O with Studio 5000

Welcome to the exciting world of Studio 5000! If you want your PLC system to work its best, you’ll need to get the hang of mapping and buffering I/O effectively. Let’s explore some best practices when mapping/buffering I/O with Studio 5000 to make sure your system is top-notch.

First off, Studio 5000 is a powerful tool that helps you organize and manage your PLC’s input and output. Think of it as your control room where you can map out how every signal moves. One of the best ways to start is by creating a clear and organized I/O map. This is like a roadmap of all your connections, showing where each sensor or device plugs in. By doing this, you avoid confusion and make it easier to troubleshoot if something goes wrong.

Another great feature in Studio 5000 is the use of tags. Tags are like labels you put on each signal to know exactly what’s happening at any point in your system. To keep things straightforward, try to use local tags, organized by user defined data types. This means creating custom categories for your signals, which makes your program more readable and easier to maintain. Imagine having a box for each type of tool in your garage — it helps you find what you need quickly!

When you’re mapping I/O, also consider using separate UDTs for inputs and outputs. UDT stands for User Defined Types, and by keeping inputs and outputs separate, your code becomes clearer and more efficient. This separation is like having different baskets for socks and t-shirts — everything’s in its place, making your life easier.

Finally, don’t forget about buffered I/O for many reasons. Buffering can protect your system from sudden changes or overloads, ensuring everything runs smoothly. In Studio 5000, make use of the built-in buffering features to handle these challenges effectively. By following these best practices, you’ll not only boost your system’s performance but also make it more reliable and easier to manage. So, dive in and make the most of what Studio 5000 has to offer!

Organizing Local Tags with User Defined Data Types

Now that you’re getting the hang of PLC I/O buffering best practices, let’s dive into the world of local tags, organized by user defined data types. This approach can make a huge difference in how you manage and understand your PLC systems.

First, let’s talk about what local tags are. In the world of PLCs, tags are like names or labels you give to each piece of data or signal in your system. Local tags are specific to a particular program or task within your PLC, which means they help you keep everything neatly organized. Think of them like the names on a school attendance list — they help you know exactly who’s present.

Now, when we say “organized by user defined data types,” we’re talking about creating specific categories for these tags. User Defined Data Types (UDTs) are custom structures you can create to group related data together. For example, if you have multiple sensors sending temperature and pressure readings, you can create a UDT that holds both types of data together. This makes your program more readable and easier to manage, like having all your art supplies in one organized kit instead of scattered everywhere.

The benefits of organizing your local tags with UDTs are immense. It not only improves the clarity of your code but also enhances maintainability. When you or anyone else looks at your program later, you’ll immediately understand what each section of code is doing. It’s like having a well-organized kitchen where you can find every spice or utensil right when you need it.

By using local tags, organized by user defined data types, you create a system that’s easy to understand and modify. This approach saves you time and frustration, especially when debugging or updating your PLC projects. So take a moment to plan and set up your UDTs wisely — your future self will thank you for it!

Using Separate UDTs for Inputs and Outputs

As you continue mastering PLC I/O buffering best practices, it’s time to explore why using separate UDTs for inputs and outputs can be a game-changer in your PLC programming. This method not only makes your code cleaner but also boosts efficiency and clarity.

Imagine your PLC program as a busy kitchen. Inputs and outputs are like ingredients and dishes. By using separate baskets for each, you avoid confusion and ensure smooth operations. Similarly, when you use separate User Defined Types (UDTs) for inputs and outputs, you’re creating distinct paths for each signal type, which helps your system run smoothly.

Let’s break it down: UDTs allow you to create custom data structures that group related information. By organizing inputs and outputs into separate UDTs, you’re essentially categorizing your data into two clear groups. This separation might seem minor, but it significantly enhances the readability of your code. It’s like having different toolboxes for your home repair and garden tools — everything stays organized and easy to find.

This practice also simplifies troubleshooting. When you encounter an issue, you can quickly pinpoint whether it’s related to an input or an output, thanks to the clear separation. It’s much like being able to immediately identify whether a problem in your house is with the plumbing or the electrical system, simply because you’ve kept everything well-organized.

Moreover, using separate UDTs for inputs and outputs aligns with best practices when mapping/buffering I/O with Studio 5000. This approach allows you to leverage Studio 5000’s capabilities to their fullest, making your system not only efficient but also scalable. Whether you’re adding new sensors or actuators, you’ll find it easier to integrate them into your existing setup without causing chaos.

In conclusion, embracing separate UDTs for your inputs and outputs is like having a map that guides you through the intricate paths of PLC programming. It brings order to complexity, paving the way for a more robust and maintainable system. So, as you continue to build and improve your projects, keep this strategy in your toolkit for success!

Reasons for Buffered I/O in PLC Systems

As you delve deeper into PLC I/O buffering best practices, understanding why buffered I/O is beneficial can unlock new levels of performance and reliability in your systems. Let’s explore the many reasons why buffering I/O is a smart move.

Think of buffered I/O as a safety net for your PLC system. In a bustling environment where multiple signals are constantly coming and going, buffering helps manage the flow smoothly, preventing your system from getting overwhelmed. Imagine a busy highway where cars are spaced out to avoid traffic jams — buffering does the same for data in your PLC, ensuring that each signal gets processed efficiently and in order.

One reason for buffered I/O is to handle sudden spikes in data traffic. Without buffering, your system might struggle to process all incoming signals at once, leading to delays or even data loss. Buffering acts like a shock absorber, smoothing out these spikes and keeping your system responsive. This is especially crucial in applications where timing and precision are key, such as in automated manufacturing lines or robotics.

Another scenario where buffering shines is in improving system reliability. By temporarily storing data, buffering ensures that your system can continue operating even if there are temporary interruptions or delays in data transmission. It’s like having a backup generator that keeps the lights on during a power outage, providing peace of mind that your operations won’t suddenly grind to a halt.

Moreover, buffered I/O enhances performance by allowing your PLC to prioritize tasks effectively. With buffered data, your system can decide which signals to process first, optimizing the overall workflow. This capability is essential in complex systems where different processes need to be synchronized to work together seamlessly.

In conclusion, incorporating buffered I/O for many reasons not only improves the performance of your PLC systems but also boosts their reliability and efficiency. Whether you’re dealing with high-speed data or complex automation tasks, buffering is a tool that helps you tackle these challenges head-on. As you continue to learn and apply these practices, you’ll find that buffered I/O is a cornerstone of robust and effective PLC programming.

Conclusion

By embracing these PLC I/O buffering best practices, you set the stage for smoother, more reliable, and efficient systems. From mapping and buffering with Studio 5000 to organizing local tags and using separate UDTs, these strategies are your key to clearer, more maintainable PLC code. Dive into your next project with confidence, and don’t forget to share your experiences and learnings with the MakerTechGuides community. Happy coding!