Troubleshooting First Layer Adhesion- Nozzle Height and Z Offset Solutions

Why the First Layer is Crucial for Successful 3D Prints

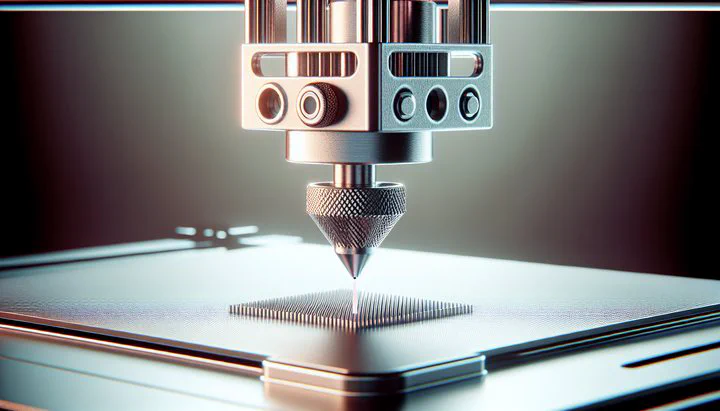

Have you ever struggled to get your first layer to stick when 3D printing? The first layer is like the foundation of a house. If it’s not strong and stable, the entire structure can suffer. This layer is crucial because it sets the stage for the rest of your print. If it doesn’t stick well to the print bed, you might end up with a failed print. That’s why understanding how the nozzle height impacts adhesion is so important.

A common problem is the nozzle being too high. When this happens, the plastic filament can’t properly stick to the print bed. You might see lines that look thin or have visible gaps between them. If the first layer isn’t smooth and even, it can cause the rest of the print to shift or detach completely. Getting the first layer to stick is a key step for successful 3D printing.

A poor first layer can show signs like uneven lines or weak adhesion. You might even see the filament dragging or curling up instead of laying flat. These are symptoms that the nozzle too high first layer not sticking issue might be at play. A well-adjusted nozzle ensures that the filament is squished slightly against the bed, creating a solid base for your print.

In the next sections, we’ll dive into specific ways to tackle these problems. From how to manually adjust the Z offset for better adhesion to making changes permanent in your printer’s settings, there are many ways to ensure your prints turn out perfectly. By focusing on the first layer, you can improve the overall quality of your 3D prints and avoid frustrating failures.

Spotting When Your Nozzle is Too High

Having trouble with your 3D prints? If your first layer isn’t sticking, it might be due to the nozzle being too high. How can you tell if this is the problem? It’s all about noticing the signs.

When your first layer isn’t sticking because of the nozzle too high first layer not sticking problem, you’ll notice some telltale signs. Take a close look at that first layer. Do you see gaps between the lines of filament? This usually means the nozzle is set too high above the print bed. The filament should be pressed down slightly to form a smooth, even surface, but if it’s too high, the lines will look thin and disconnected.

Another sign of a high nozzle is poor extrusion. If the filament is curling up or dragging along the bed, it means the filament isn’t adhering properly. The first layer might even peel away or not stick at all, causing the entire print to fail. Ideally, the first layer should have continuous, even lines that are slightly squished together. This creates a solid base for the rest of your print.

To fix this, you’ll need to adjust the nozzle height. In the next sections, we’ll discuss how you can make a manual adjustment of Z offset value to solve this problem. By identifying these signs early, you can avoid wasting time and material on failed prints. Understanding the symptoms of a nozzle being too high is the first step to getting that perfect first layer to stick every time.

How to Manually Adjust Z Offset for Better Adhesion

Now that you’ve identified that the nozzle being too high is causing your first layer issues, it’s time to fix it with a manual adjustment of Z offset value. This may sound a bit technical, but don’t worry—I’ll guide you through it step by step.

First, let’s understand what Z offset is. The Z offset is a setting that controls the distance between the print bed and the nozzle. Adjusting this value can help you get the first layer to stick properly by ensuring the nozzle is at the right height. If your nozzle is too high, you’ll need to decrease the Z offset value to lower the nozzle closer to the bed.

To start, you’ll need to access your printer’s settings. The exact steps can vary depending on your printer model, but generally, you’ll find the Z offset settings in the firmware menu. Look for an option labeled “Z Offset” or something similar on your printer’s interface. If you can’t find it, check your printer’s manual or the manufacturer’s website for guidance.

Once you’ve located the Z offset setting, adjust it in small increments. Decrease the value slightly and then test by printing a small patch on the bed. Observe if the first layer is sticking better. Repeat this process until the first layer sticks smoothly and evenly. Remember, small adjustments can make a big difference, so go slow and steady.

For some printers, you may need to manually edit the offset directly in the G code. This involves changing the line that specifies the Z offset value. Be cautious when editing G code, and make sure to save a backup of your original settings. If you’re unsure, many online communities, like the ones on MakerTechGuides, can offer advice and support.

By mastering the manual adjustment of Z offset value, you’ll solve the problem of the nozzle too high first layer not sticking. This adjustment is crucial for achieving that perfect first layer, ultimately leading to successful 3D prints. In the next section, we’ll explore how to incorporate these adjustments into your printer’s G code for consistent results.

Making Z Offset Adjustments Permanent in G Code

You’ve tackled the manual adjustment of Z offset value, but what if you want to make these changes permanent? That’s where modifying your printer’s G code comes in. By incorporating the Z offset adjustments directly into your G code, you ensure that each print starts with the nozzle at just the right height, helping your first layer to stick consistently.

G code is the language your 3D printer understands. It tells the printer how to move, where to move, and what to do when it gets there. To adjust the Z offset in G code, you’ll need to find the line that specifies the Z starting position. This is usually near the beginning of the code, marked by a command like G92 Z0.2, where the number represents the offset value.

To begin, open your slicer software and look for the settings that allow you to customize the start G code. Here, you can add or modify the Z offset command. If your nozzle is too high, decrease the offset value slightly. For example, if the current command is G92 Z0.2, you might change it to G92 Z0.1 to lower the nozzle.

After making your adjustments, save the changes and run a test print. Check if the first layer adheres better. It’s crucial to test after each change because even a small modification can have a significant impact on print quality. If needed, continue tweaking the offset until you achieve the perfect first layer.

Be cautious of common mistakes, like setting the offset too low, which can cause the nozzle to press too hard against the bed and damage it. Always make incremental adjustments and monitor the results carefully. If you’re not confident in editing G code, seek advice from online forums or communities like the ones on MakerTechGuides.

By incorporating the Z offset adjustments into your G code, you solve the nozzle too high first layer not sticking issue for good. This approach not only saves time but also ensures that you consistently achieve high-quality prints with a solid first layer foundation. In the next section, we’ll share additional tips to further enhance first layer adhesion and prevent future problems.

Top Tips for Perfect First Layer Adhesion

You’ve learned how to adjust the Z offset and modify G code to fix the nozzle too high first layer not sticking issue. But there are even more tips and tricks to help you achieve a perfect first layer every time. Let’s explore some of these strategies to enhance your 3D printing experience.

First, always start with a clean print bed. Dust, oil, or leftover filament can prevent the first layer from sticking. Use isopropyl alcohol or a mild detergent to wipe down the bed before each print. A clean surface ensures that the filament can adhere properly without any interference.

Next, make sure your print bed is level. An uneven bed can lead to areas where the nozzle is too high or too low, causing poor adhesion. Most 3D printers have a bed leveling feature, either manual or automatic. Take the time to check and adjust the bed leveling regularly. A level bed is critical for a uniform first layer.

Using adhesives can also help the first layer to stick better. Some makers use glue sticks, hairspray, or special 3D printing adhesives on the print bed to enhance adhesion. Just apply a thin layer before starting your print. Make sure to choose an adhesive that’s compatible with your printer and filament type.

Another tip is to adjust the print speed and temperature. Printing the first layer slower gives the filament more time to stick to the bed. Increasing the bed temperature can also improve adhesion, as it helps the filament bond better with the surface. Check your filament’s recommended settings and experiment with small adjustments to find what works best for your setup.

Lastly, consider using a brim or a raft in your slicer settings. These features add extra material around or under your print, increasing the surface area for adhesion. They can be particularly helpful for prints with small contact points on the bed.

By implementing these tips, you can further enhance your 3D prints and prevent the nozzle being too high from causing first layer issues. Remember, achieving a perfect first layer is key to successful 3D printing. With these strategies, you’ll be well on your way to creating high-quality prints every time.

Feel free to share your experiences or ask questions in the comments or join discussions on relevant community subreddits like 3DPrinting and MakerTechGuides. Your feedback and participation help strengthen our community of makers!