Mastering Function Block Access State in Siemens S7

Mastering Function Block Access State in Siemens S7

Welcome to MakerTechGuides! If you’re diving into Siemens S7 PLCs, understanding function blocks is a crucial step. Let’s explore what these blocks are and how they can streamline your automation projects.

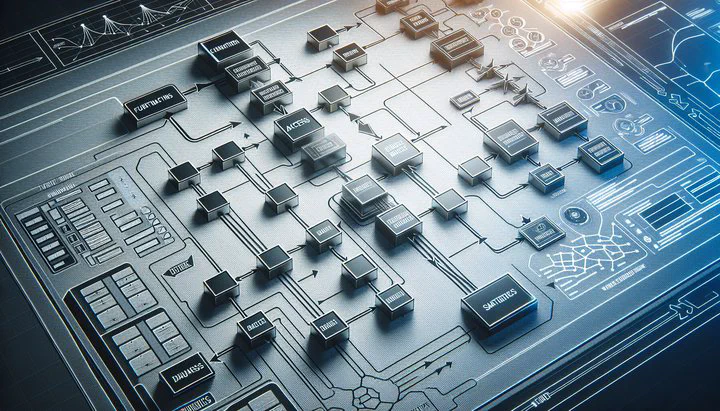

Understanding Function Blocks in Siemens S7

Function blocks in Siemens S7 are like Lego pieces for your PLC. They break down complex problems into simple, manageable tasks. Imagine building a robot: instead of one big, confusing mess, you have separate parts like arms or wheels. Each part has a job, making the robot easier to control.

In Siemens S7, function blocks help you organize code and manage logic. They let you write a piece of code once and use it in different parts of your project. Think of them as a recipe you can reuse. For example, if you create a function block to control a motor, you can use it for any motor without rewriting the code.

These blocks are key for managing complex logic in automation systems. They allow access to a state in Siemens S7 and update it as needed. This helps you track what’s happening in your system, ensuring it runs smoothly. By organizing your code with function blocks, you gain control over your automated systems.

In short, function blocks in Siemens S7 are essential for organizing and managing your projects. They simplify your code, make it reusable, and help maintain control. Understanding them is the first step to mastering function block access state in Siemens S7.

Accessing and Updating States in Siemens S7

Now that you know what function blocks are, let’s learn how to work with their states. Accessing and updating these states ensures your automation system runs smoothly.

To access to a state in Siemens S7, start by opening the function block. Each block has variables and states you can adjust. Think of these as levers and buttons that change how your system behaves. Use programming languages like Ladder Logic to perform these actions.

To update a state, decide what event should trigger the change. For instance, if you’re controlling a conveyor belt, update the state when a sensor detects an item. Use instructions in your program to check conditions and change the state. This is called a function block update state in Siemens S7.

Imagine you have a motor controlled by a function block. You want it to start when a button is pressed and stop when another is released. Write a program that updates the motor’s state based on these button inputs. The program checks the buttons’ status and updates the motor’s state to running or stopped.

By mastering these steps, you’ll effectively manage function block states, ensuring your Siemens S7 system operates as intended. This skill is crucial for excelling in function block access state in Siemens S7 management.

Global State Management Techniques

As you get comfortable with Siemens S7, you’ll want to manage states across different function blocks. This is where global state management in Siemens S7 comes in. It keeps your system consistent and reliable, even with multiple function blocks.

Picture a factory with machines that must work together smoothly. Each machine has a function block, but they need to communicate. Global state management tracks states across all blocks, ensuring seamless transitions between tasks.

To manage global states, set up global variables. These act like shared notes each function block can read and update. Think of them as a central bulletin board for machine updates. This creates a system where each block knows what’s happening in the program.

Use a central control block to oversee global states. It takes inputs from all blocks and updates global variables. For example, if a pump needs to stop when a tank is full, the control block manages this by checking the tank’s state and sending a stop command.

Mastering global state management in Siemens S7 is key to building reliable automation solutions. By using global variables and a central control block, you ensure all parts work together harmoniously.

Practical Example: Ladder Program for Pumps

Let’s apply what we’ve learned with a practical example: a ladder program for pumps in Siemens S7. This will show you how to manage function block access states.

Imagine you control pumps in a water treatment plant. Each pump turns on or off based on water levels. A ladder program visualizes and controls these operations.

Create a function block for each pump. Each block has a state indicating if the pump is on or off. Use Ladder Logic to write the program. Inputs like sensors detect water levels, and outputs control the pump’s state.

Here’s how it works: when water in a tank drops, a sensor signals the function block to turn the pump on. When water is high, the sensor tells the program to turn the pump off. This is a function block update state in Siemens S7, where the state changes based on inputs.

This setup automates pump operations, reacting to water levels without manual intervention. The ladder program helps monitor and troubleshoot if needed. If a pump doesn’t turn on, check the program for sensor issues or logic errors.

Using a ladder program for pumps in Siemens S7 showcases function blocks’ power and highlights managing access to states. By automating pump operations, you ensure reliable water management. As you design these programs, you’ll gain confidence in handling complex tasks, mastering function block access state in Siemens S7.

Best Practices and Troubleshooting

Now, let’s explore best practices for managing function block access states in Siemens S7. These tips will help you create reliable automation systems.

First, keep your code organized. Label function blocks clearly and use descriptive variable names. This makes it easier to understand and troubleshoot your program.

Second, test your function block updates regularly. Simulate operations to catch errors early, especially with a function block update state in Siemens S7. Testing ensures your state changes trigger correctly.

Use global variables wisely for global state management in Siemens S7. They are powerful but can cause confusion if not used properly. Ensure each block updates global variables in a controlled manner.

When troubleshooting, start with the basics. Verify sensors and inputs work correctly. If a state doesn’t update, it might be due to a faulty sensor or misconfigured input. Review your ladder program for logic errors.

Finally, document changes to your program. Keeping a log of modifications helps track what works and doesn’t, making it easier to revert changes if needed.

By following these best practices, you’ll effectively manage function block access state in Siemens S7. With experience, you’ll create robust automation solutions that are both efficient and reliable.

Conclusion

You’ve learned how to master function block access states in Siemens S7! Now, put this knowledge into practice. Visit MakerTechGuides for more guides and join our community subreddits to connect with fellow enthusiasts. Keep experimenting and refining your skills. The more you practice, the more confident you’ll become in tackling automation challenges.