Solving Ender 5 Plus Direct Drive Z Layering Problems

Solving Ender 5 Plus Direct Drive Z Layering Problems

Are you ready to take your Ender 5 Plus to the next level? Upgrading to a direct drive system can unlock new potential, but it might also introduce some challenges. If you’re encountering Ender 5 Plus direct drive Z layering problems, you’re not alone. This guide will help you navigate these issues and improve your 3D printing experience.

Understanding the Ender 5 Plus and Direct Drive Systems

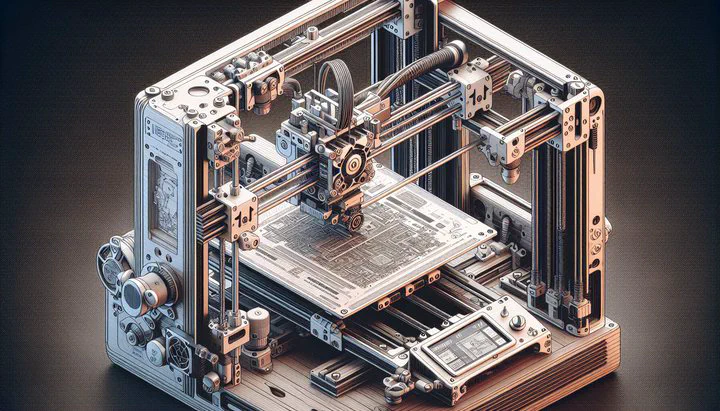

The Ender 5 Plus is a popular 3D printer known for its large build volume and reliable performance. It’s a favorite among hobbyists and professionals who love creating detailed models and prototypes. The printer comes with a Bowden extruder setup, which places the extruder motor away from the print head. But some users want to upgrade to a direct drive system for better control and precision, especially when printing with flexible filaments.

Think of a direct drive system like having a pen directly in your hand rather than attached to a stick. This setup mounts the extruder directly on the print head, making it easier to print with tricky materials like TPU or TPE. However, upgrading your Ender 5 Plus to a direct drive system can also bring some challenges. You might face new issues like Z layering problems, including Z-wobble, where the layers of your print don’t line up perfectly.

Why do these issues happen? The added weight of the direct drive can change how your printer moves, leading to problems with layer alignment. Z-wobble layering issues can make your prints look uneven or cause layer shifts, which is frustrating when you want a smooth finish. But once your setup is optimized, the joy of printing with flexible materials is worth it.

In this article, we’ll explore these challenges and provide solutions to help you enjoy the benefits of a direct drive system. By understanding the Microswiss NG direct drive system and the Creality silent drive main board, you’ll be better prepared to tackle any issues. Stay tuned as we dive into the details and learn how to overcome these Z layering problems for the best printing results.

Identifying Z Layering Problems

When upgrading your Ender 5 Plus to a direct drive system, you might encounter Z layering problems. These issues can make your prints look less than perfect and can be frustrating for anyone wanting a smooth, professional finish. So, what exactly should you look for?

One common issue is Z-wobble layering issues. Imagine building a tower of blocks where some blocks are slightly off-center. This happens when the layers in your print don’t align correctly, causing a wavy or uneven surface. You might notice that the sides of your print look bumpy instead of smooth. This is often due to the additional weight of the direct drive system, which can affect how the printer’s Z-axis moves.

Another sign of Z layering problems is when you see layer shifts. This means that the layers of your print don’t line up with each other, creating a staircase effect on the edges of your model. These shifts can occur if the printer’s movements aren’t perfectly synchronized, sometimes because of vibrations or misalignments in the setup.

To help you spot these problems, it can be useful to look at examples. Imagine printing a tall, straight tower. If the Z-wobble is affecting your print, the tower will look like it has ridges running up and down its sides. Or, if there’s a layer shift, the tower might look like it’s twisted slightly to one side.

Identifying these problems is the first step to fixing them. With the right adjustments and tools, like the Microswiss NG direct drive system and the Creality silent drive main board, you can overcome these challenges. In the next sections, we’ll explore how these tools can help and what steps you can take to ensure your prints come out looking great.

The Role of the Microswiss NG Direct Drive System

The Microswiss NG direct drive system is a popular upgrade for the Ender 5 Plus, and it can significantly impact how your printer handles Z layering problems. This system is designed to provide better control over filament feeding, especially when working with flexible materials. However, it’s important to understand both its benefits and how it might contribute to issues like Z-wobble layering issues.

First, let’s look at what makes the Microswiss NG special. This direct drive system is known for its robust construction and precision engineering. It mounts the extruder directly on the print head, which can reduce the chances of filament slipping or jamming. For many users, this leads to smoother extrusion and fewer print errors. When installed correctly, the Microswiss NG can improve print quality by ensuring consistent filament flow.

However, the added weight of the Microswiss NG system can also introduce challenges. Since the extruder is now closer to the print head, it can affect how the printer’s Z-axis moves. This can lead to Z-wobble layering issues, where layers don’t align as they should. To minimize this, it’s crucial to carefully install and calibrate the system. Think of it like tuning a musical instrument—every detail matters. Make sure all screws and components are tightly secured, and consider adjusting the printer’s acceleration and jerk settings to compensate for the extra weight.

Another tip is to check the bed leveling. A well-leveled bed can help counteract the effects of Z-wobble by providing a stable base for your prints. Regularly inspect the printer’s frame and ensure it’s tight and properly aligned. This can prevent unwanted vibrations that might contribute to Z layering problems.

In summary, the Microswiss NG direct drive system offers numerous benefits for the Ender 5 Plus, but it’s essential to be aware of the potential for Z-wobble. By taking the time to properly install and calibrate the system, you can enjoy the advantages of direct drive while reducing the risks of layering issues. With the right setup, your 3D prints can achieve the high-quality finish you’re aiming for.

Optimizing with the Creality Silent Drive Main Board

The Creality silent drive main board is another important component that can help solve Z-wobble layering issues on your Ender 5 Plus. This main board is designed to reduce noise and improve the overall performance of your printer, making it a valuable upgrade when dealing with Z layering problems.

One of the key features of the Creality silent drive main board is its ability to significantly reduce the noise produced by the stepper motors. This is achieved through more advanced motor drivers that ensure smoother and quieter operation. By reducing these vibrations, the board helps keep your prints stable, minimizing the risk of Z-wobble layering issues that can arise from a shaky Z-axis. Enjoy a quieter workspace while achieving better prints!

Installing the Creality silent drive main board is a straightforward process, but it’s important to follow the steps carefully to ensure everything is connected properly. Begin by unplugging your printer and opening the control box to access the existing main board. Carefully detach each connector and take note of where each one goes. This will help when you install the new board. Once the Creality silent drive main board is in place, reconnect each cable to its corresponding port, ensuring a snug fit for all connections.

After installation, you’ll want to configure the board to optimize its performance. This usually involves updating the firmware to the latest version provided by Creality. Firmware is like the software that runs your printer, helping it perform tasks correctly. Updated firmware can include enhancements and bug fixes that improve how your printer operates, further reducing Z layering problems. Be sure to check Creality’s website or community forums for the latest firmware updates and installation guides.

By incorporating the Creality silent drive main board into your setup, you not only reduce noise but also enhance print quality by addressing the factors that contribute to layer misalignment. With precise adjustments and careful installation, you can significantly improve your Ender 5 Plus’s ability to produce smooth, high-quality prints, even when using a direct drive system. This upgrade, combined with the Microswiss NG direct drive system, can provide a powerful solution to overcoming the common challenges faced with Z layering issues.

Calibrating E-Steps and Flow for Better Prints

To tackle Ender 5 Plus direct drive Z layering problems, calibrating your printer’s e-steps and flow is crucial. These settings ensure your 3D printer extrudes the right amount of filament, which is key to achieving smooth and even layers. Let’s dive into how you can calibrate these settings to overcome Z-wobble layering issues and improve your print quality.

-

E-steps calibration is the first step you need to take. E-steps, or “extruder steps,” determine how much filament is pushed through the nozzle with each rotation of the extruder motor. If your e-steps are off, your printer might extrude too much or too little filament, leading to uneven layers or gaps in your prints. To calibrate the e-steps, start by marking 100mm on a piece of filament and load it into the extruder. Next, tell your printer to extrude 100mm of filament. Measure how much filament was actually extruded, and use this measurement to adjust the e-steps setting in your printer’s firmware. This fine-tuning is essential for solving Z-wobble layering issues.

-

Flow calibration focuses on the flow rate, or extrusion multiplier, a setting that tells your printer how fast to push the filament through the nozzle. If the flow rate is too high or too low, it can affect layer adhesion and print dimensions. To calibrate the flow rate, print a simple test cube and measure its dimensions. If the walls of the cube are thicker or thinner than expected, adjust the flow rate accordingly. This adjustment will help ensure that layers stick together properly, reducing the risk of Z layering problems.

Finally, remember to test your settings. Once you’ve adjusted the e-steps and flow rate, print a few test models to see how these changes affect print quality. Look for improvements in layer smoothness and alignment. You might need to make slight tweaks to get everything just right, but with patience, you’ll see a noticeable difference in your prints. Don’t be afraid to tweak settings—it’s all part of the fun of 3D printing!

By taking the time to properly calibrate the e-steps and flow settings on your Ender 5 Plus, you’re setting yourself up for success. These adjustments are a vital part of solving Z-wobble layering issues and achieving the high-quality prints you’re aiming for. With your Microswiss NG direct drive system and Creality silent drive main board finely tuned, you can enjoy smoother, more precise printing every time.

Related

- Effectively Managing TIA Software Changes with VM Snapshots

- Mastering Auto-Complete with Shared VarSets in FreeCAD

- Troubleshooting Flashforge Adventurer 4 Printing Issues

- Troubleshooting Issues When Moving ViewME Project Folder to OneDrive

- Mastering Macros in FreeCAD for Object Copying with Internal Names