3D Scanner Suggestions for Mechanical Parts

Introduction to 3D Scanners for Mechanical Parts

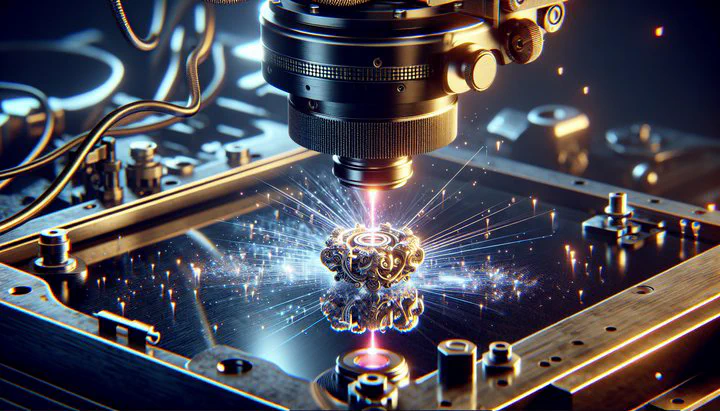

When you’re working with mechanical parts, accuracy is everything. That’s where 3D scanners come in handy. These devices help capture detailed shapes of parts, making sure every curve and crevice is recorded. Whether you’re designing new pieces or figuring out how an old part works, 3D scanners act as your assistant to pick up my slack, ensuring nothing is missed.

In the world of making things, having a 3D scanner is like having an extra set of super eyes. These scanners help create digital models of real objects. This helps engineers and makers like you see and change parts more easily. Imagine trying to recreate a complex gear without a detailed digital model—it would be like solving a puzzle without a picture! By using a 3D scanner, you can save time and reduce mistakes, making your work smoother and more efficient.

However, scanning mechanical parts isn’t always easy. Some parts have small details that can be hard to capture. This is why picking the right scanner is important. Not all scanners are the same; some are great at capturing small details, while others are better for bigger objects. That’s why it’s important to find the right match for your needs, whether it’s a cheap 3D scanner for scanning mechanical parts or something more advanced. By knowing what different 3D scanners can do, you can make smart choices and improve your projects.

In the following sections, we’ll dive deeper into the features that matter most when selecting a 3D scanner for mechanical parts. We’ll also explore some affordable options and take a closer look at the Revopoint Mini/Mini2, known for its accuracy and reliability. Whether you’re a hobbyist or a professional, this guide will help you find the best 3D scanner suggestions for mechanical parts.

Key Features to Consider in a 3D Scanner

When you’re looking for the best 3D scanner suggestions for mechanical parts, it’s important to know what to look for. These features can greatly impact how well your scanning goes. Let’s explore some of the most important aspects.

First up is resolution. This tells you how much detail your scanner can capture. For mechanical parts with small details, a high-resolution scanner is a must. It ensures that every tiny feature is shown in the digital model. Think of it like a camera—higher resolution means clearer pictures. So, always check the resolution to make sure it fits your project’s needs.

Next is accuracy. This shows how close the digital model is to the real-life object. If you’re using the scanner for parts that need to fit together perfectly, accuracy is key. A scanner with high accuracy will help you make parts that are true to size, avoiding any costly mistakes.

Scan speed is another feature to keep in mind. Faster scan speeds can save you time, especially if you’re scanning lots of parts. But don’t give up detail for speed—sometimes a slower scan can capture more information, which is vital for complex parts. Balancing speed with detail is important.

Finally, consider software compatibility. The scanner’s software should be easy to use and work well with your existing tools. Some scanners come with software that allows you to edit and refine your scans. Check if the scanner’s software can work with the design programs you already use, like CAD software.

By focusing on these key features—resolution, accuracy, scan speed, and software compatibility—you’ll be better equipped to choose the right 3D scanner assistant to pick up my slack. Remember, the best scanner for you depends on your specific needs and budget, whether you want cheap 3D scanners for scanning mechanical parts or a more premium option. In the next sections, we’ll review some affordable scanners and delve into the Revopoint Mini/Mini2 to see how they stack up in terms of accuracy and reliability.

Affordable 3D Scanners for Mechanical Parts

Finding the right 3D scanner suggestions for mechanical parts that won’t break the bank can be a game-changer for hobbyists and small businesses alike. Luckily, there are several cheap 3D scanners for scanning mechanical parts that offer a great balance between cost and performance.

One popular option is the Creality CR-Scan 01. This scanner is known for its easy use and decent accuracy. It’s a great pick if you’re just getting started with 3D scanning or if you have a tight budget. The CR-Scan 01 captures details well enough for most small to medium-sized mechanical parts, making it a solid choice for hobby projects or small-scale production.

Another affordable model to consider is the XYZprinting Handy Scan. This handheld scanner is lightweight and portable, making it ideal for scanning parts in different locations. It’s user-friendly, with software that simplifies the scanning process. While it might not capture the tiniest details, it’s good for many mechanical uses and offers excellent value for its price.

The Matter and Form V2 is also worth checking out. It’s a desktop scanner that offers high resolution for its price range, making it a good option for capturing smaller details in mechanical parts. Its folding design saves space, and it comes with easy software. This scanner is great for makers who need more detail without spending too much.

When comparing these cheap 3D scanners for scanning mechanical parts, consider what features are most important for your projects. If portability is key, the Handy Scan might be your best bet. For higher detail, the Matter and Form V2 is a strong contender. And for an all-around reliable and easy-to-use scanner, the Creality CR-Scan 01 could be the perfect fit.

Each of these scanners has its strengths, so think about the specific needs of your projects when making a decision. The right scanner can become your 3D scanner assistant to pick up my slack, helping you achieve precision and efficiency in your work without a hefty investment. Up next, we’ll take a closer look at the Revopoint Mini/Mini2 to see how it compares in terms of accuracy and reliability.

Revopoint Mini/Mini2: Accuracy and Reliability

When it comes to scanning mechanical parts with precision, the Revopoint Mini and Mini2 stand out for their accuracy and reliability. These scanners are popular among both hobbyists and professionals who need detailed scans of intricate parts. Let’s dive into what makes these models a top choice for those seeking 3D scanner suggestions for mechanical parts.

The Revopoint Mini is known for its high-resolution scanning capabilities, making it perfect for capturing small details. With a resolution of up to 0.02mm, this scanner can pick up tiny features that other models might miss. This level of detail is crucial when working with mechanical parts that require precise measurements and fits. Whether you’re recreating a component or designing something new, the Mini ensures you get an accurate digital representation.

The Mini2 builds on the strengths of its older model, offering even better performance. It boasts improved scanning speed and stability, which means you can work more efficiently without sacrificing quality. The Mini2 is also highly reliable, providing consistent results that you can trust. This makes it an excellent 3D scanner assistant to pick up my slack, ensuring that every scan you conduct meets your high standards.

Users of the Revopoint Mini and Mini2 often praise the ease of use and the intuitive software that comes with these scanners. The software allows for easy editing and refining of scans, helping you integrate them seamlessly into your workflow. Compatibility with various design programs means you can move from scanning to design with minimal hassle.

Feedback from the community highlights the Revopoint Mini/Mini2 accuracy and reliability in capturing mechanical parts with intricate geometries. Many users appreciate how these scanners help them achieve professional-level results without needing to invest in more expensive equipment. Whether you’re scanning gears, brackets, or other detailed components, these models consistently deliver high-quality digital models.

In summary, the Revopoint Mini and Mini2 are excellent choices if you’re looking for reliable and accurate 3D scanning solutions for mechanical parts. Their ability to capture fine details and their user-friendly design make them a valuable tool in any maker’s toolkit. As you consider your options, keep in mind the strengths of these models and how they can enhance your projects. Up next, we’ll explore some practical tips for scanning small details effectively.

Tips for Scanning Small Details

Scanning mechanical parts with intricate details can be challenging, but with the right approach, you can achieve impressive results. Here are some practical tips to help you capture those tiny features effectively, making your 3D scanner assistant to pick up my slack when precision is key.

First, prepare your mechanical parts thoroughly before scanning. Clean the parts to remove any dust, oil, or debris that might affect the scan quality. Even small particles can create noise in your scan, so ensuring a clean surface is essential. Use a soft brush or compressed air to gently clean the parts, focusing especially on the small nooks and crannies where dirt might accumulate.

Positioning is another critical aspect of scanning small details. Make sure your part is stable and well-lit to avoid shadows and reflections that can distort the scan. Consider using a turntable if your scanner supports it; this can help you capture all angles of the part without having to reposition it manually. If you’re working with very small parts, you might need to use mounting putty to keep them steady.

Adjust your scanner’s settings to optimize for detail capture. This might mean lowering the scan speed to allow more time for the scanner to pick up fine features. Check the resolution settings and choose the highest resolution your scanner can handle for capturing intricate details. Remember, this might increase the scan time, but the trade-off is worth it for the added precision.

During the scanning process, use contrast-enhancing techniques to help your scanner detect small features. Spraying a light coat of scanning spray or powder can make surfaces more uniform and easier for the scanner to read, especially if the parts are shiny or transparent. This simple step can significantly enhance the detail captured in your scans.

Finally, troubleshooting common issues can save you time and frustration. If your scans aren’t capturing the details you need, try adjusting the distance between the scanner and the object. Too close or too far can affect the detail level. Check for any software updates that might improve performance or add new features to your scanner. Community forums and user groups can also be great resources for tips specific to your scanner model.

By following these tips, you’ll be well-equipped to capture the small details in your mechanical parts accurately. With practice, your scanning skills will improve, and your 3D scanner assistant to pick up my slack will become an invaluable tool in your creative and engineering endeavors. Armed with this knowledge, you’re ready to take on even the most intricate scanning challenges with confidence.

Conclusion

Choosing the right 3D scanner for your mechanical parts can make a big difference in your projects. By understanding the key features and considering affordable options like the Revopoint Mini and Mini2, you can find a scanner that fits your needs and budget. Remember to prepare your parts, use the right settings, and take advantage of tips to capture small details. As you explore the world of 3D scanning, share your experiences and ask questions in the comments or on community forums. Your journey in mastering 3D scanning is just beginning!